The cable spent the night on the telescope floor, snaked past the red UW flag on the pier...

First up, Johan & Nicolaas finished up the installation of the maypole - the system that keeps the cable strands in the right orientation & prevents the structure rotation from putting strain on them.

|

Two of the rings had to be attached at the top of the hole before being lowered into the space below. The other two are attached at the bottom & top of the pintle bearing.

|

The HRS fibre cable gets to join the NIR ones in this nifty new system, seen in the 4 o'clock positioning the pic below.

|

Happily, the long-awaited lift technicians finally showed up & set about fixing the elevator that's been offline for a couple of weeks.

|

But they weren't finished in time to spare Joshua the hand-freezing climb up the ladder that the poor Tech Ops guys have been needing to do all this time.

|

With all the ropes in place, it was time to take up our positions.

|

Up, up & away!

|

To be received by Jonathan, Alrin & Joshua.

|

Safely onto the platform!

|

An anxious crowd watched from below, including those packed into the visitors gallery.

|

Here's Sabyasachi enquiring how all the fibres feel about the day so far...

|

Then, in true South African fashion, it was time for yet another bout of load-shedding to add to the drama. The whole dome was briefly plunged into darkness while we made the switch to generator power - all too frequent an exercise these days.

|

With the lights back on, the guys made their way up onto the tracker to start the non-trivial task of threading all the fibre cables through the rho wrap.

|

Meanwhile, down in the instrument enclosure, Mike & Joshua got busy routing the other end of the fibres into their new home.

|

Here's the part of the maypole attached to the bottom of the pintle bearing, just above the HRS enclosure. The linear slides allow the whole lot to smoothly slide vertically (while gently spiralling up & down) in response to rotation of the telescope structure.

|

Midst all this action, our interns (most from Wits University in Joburg, & one from Cape Town) arrived. They drove up from Cape Town today, along with Moses, the SALT astronomer (SA) responsible for the NIR on the SALT side.

|

Lee & Xola also came up on the transport today & will be the observers (SALT astronomer & SALT operator, SA & SO) on duty this coming week. This was the first chance for all of them to get to see the new spectrograph :)

|

Then Vasili, Cathy, Coral, Justine & Abby popped upstairs to soak up some telescope vibes in the rather chilly dome.

Inside the enclosure, the UW guys were busily installing the 8 V-groove blocks to populate the slit.

|

Here's the fully populated slit, with all 8 blocks installed & aligned to form the required arc using the specially made alignment plate attached on the right.

|

After doing the fibre positioning with the slit horizontal, the aligned slit could be mounted vertically to the back of the collimator, directed into the slot in the first element of the collimator lens barrel.

|

If we're to get first-light before the UW team have to leave on Friday, they need to finish up all the work inside the enclosure tonight, so that they can start the cool-down to -40C, which takes about 20 hours. So the thoroughly exhausted Joshua slogged on to finish securing all the fibres & installing supports to provide strain-relief for all the bundles. Here he's caught taking a slow-blink micro-nap on the job, while Marsha looks on from the doorway...

|

Mike in the meantime set about fixing the louvres on one of the sets of cooling units inside the enclosure. A fairly scary stage to be climbing on the instrument frame, & asking at one point for a hammer of whatever size is available... 😱

|

Somehow he got all that done without incident & Joshua finished up the strain-relief system, which leaves the fibres in a safe & comfortable state.

|

The final steps were optical ones: Mike installed the VPH grating - a ridiculously quick procedure, thanks to his wonderful design on the grating mechanism!

|

Then he swiftly removed the cover on the front of the camera barrel.

|

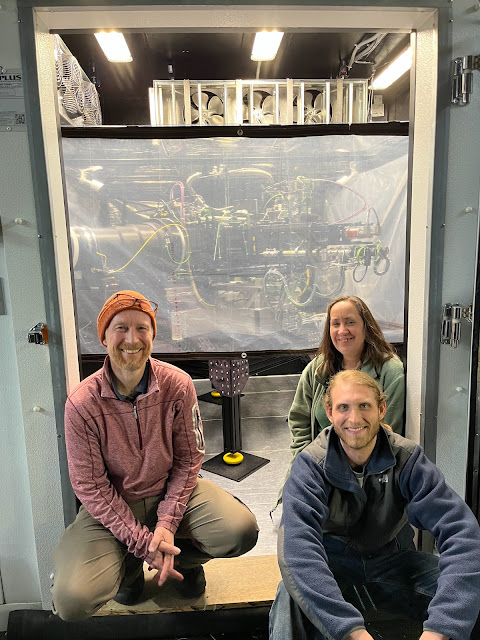

Before shutting the freezer door, they paused for a moment to indulge the pesky photographer!

|

A quick check of all the goings on inside the controller unit for the enclosure...

|

Before starting the cooldown process at about 00:20.

|

Safety first: the bolt through the hole in the door handle to prevent the door from accidentally getting opened, & a "no trespassing" sign to discourage would-be tourists.

|

That was Quite enough for one day - now for a few hours sleep (& surely another miserable cold shower in the morning 😭) ahead of what will be yet another very busy day!

Comments

Post a Comment